The following is an excerpt from the “History” portion of QC’s most recent business plan revision (ES-R4). Interested parties should contact QC directly to request a full version of the business, marketing, and financial growth plan for 2015 thru 2018.

Startup

QC Commercial, LLC (henceforth QC) was founded by Russ Phillips in 2002 as Quote & Coat Painting. After registering the company as a sole proprietorship on August 1, Mr. Phillips spent the next six months writing the startup plans and performing an array of startup activities. The company did not start generating income until 2003 after it was awarded a $60K painting contract as part of a $3M estate home construction project in the upscale Wakefield community in North Raleigh. That first year in business QC grossed $190K in total revenue which yielded approximately 25% in pretax profit.

During the first three years of operation QC competed exclusively in the residential new construction and existing home repaint markets. With the exception of a handful of estate homes, the average project grossed roughly $5K with pretax earnings running in the 20 to 25 percent range. With no salesman on staff and working with a nominal advertising budget, revenues grew at an uninspiring rate to $294K in 2005, yielding less than expected earnings.

During the business’ third year of operation Mr. Phillips decided to abandon the residential sector completely and pursue only commercial1 and industrial2 opportunities. Mr. Phillips took out low budget ads in The Blue Book, an advertising publisher targeting commercial general contractors, commercial property owners, and property management firms. The company grew by another $100K in 2006 while working almost exclusively in the commercial and industrial markets. The move from residential to commercial projects resulted in immediate increases in profit margins.

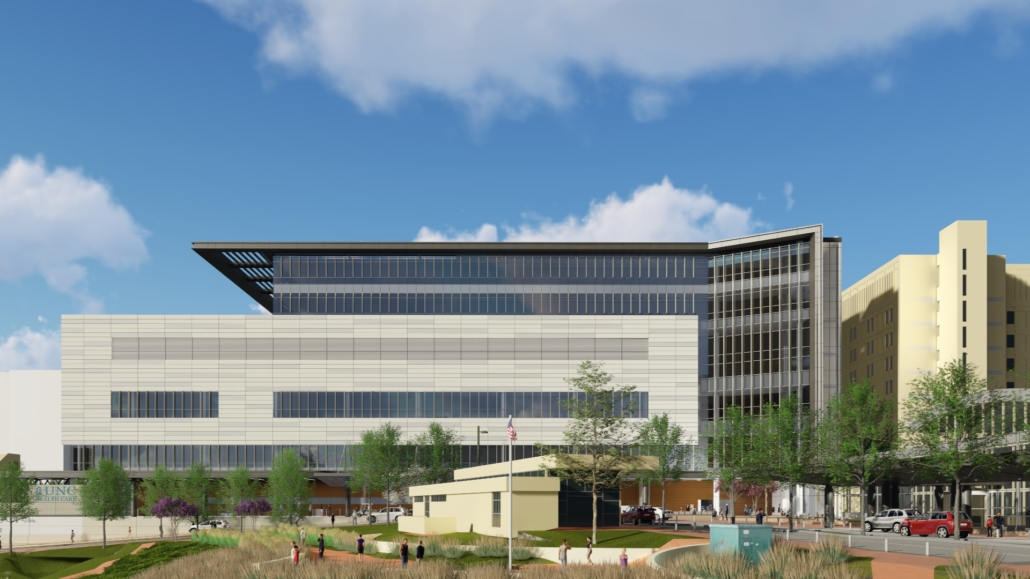

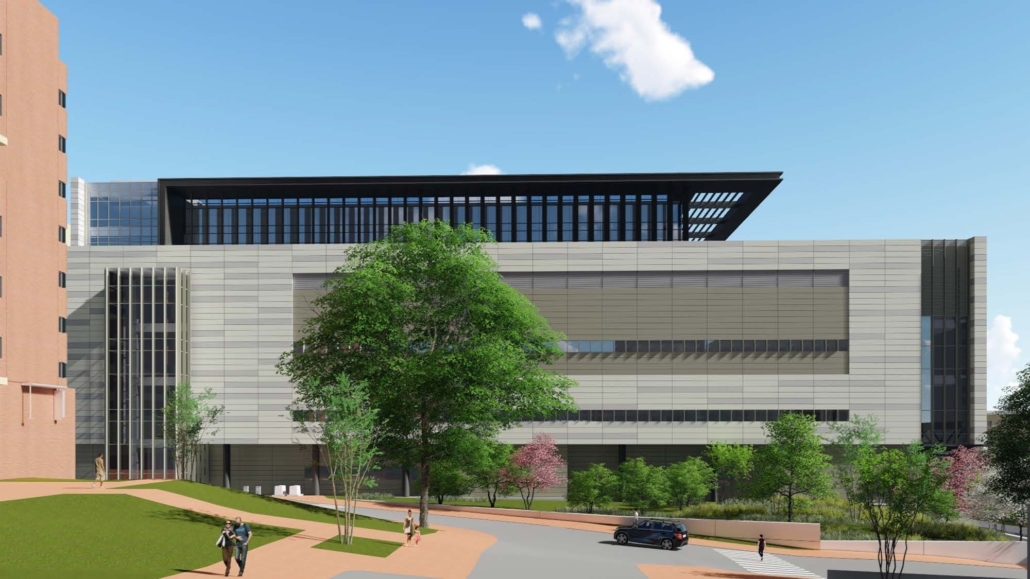

By 2007 QC was installing complex coating systems for very large and renowned corporations such as Pfizer, Progress Energy, Becton-Dickinson, and Merck. At this stage QC was contracting through a Construction Manager3 (CM) or General Contractor4 (GC)—never directly with the project owner. The CMs/GCs QC partnered with included Zachary, BE&K (now KBR), MJ Harris, US Builders, and Fortney & Weygandt.

Brand Demarcation

It quickly became obvious to Mr. Phillips that the company should only operate within the confines of the commercial/industrial market. After spending several years working in the high-tech world of Printed Circuit Board manufacturing as a Quality Engineering Manager, the Founder was able to identify a level of professionalism and quality control in industrial construction that was totally absent in the residential market. This provided an opportunity for Mr. Phillips to showcase his ability to develop and implement ISO5 compliant operating procedures and, once implemented into the company’s operations, distinguish QC from all of the other regional painting contractors.

QC has now established itself as an industrial painting contractor. It recently invested $6K in website upgrades, business card redesign, new logo and tag line, and a redesign of company apparel, i.e., t-shirts, golf shirts, and safety vests, etc. These changes are part of a renewed focus on building the company brand. Additional proactive efforts are being made to re-launch the company and are further expounded in Section 3 Marketing Strategy.

QC’s active customer base includes commercial/industrial GCs and CMs, as well as industrial manufacturing companies (OEMs)6. Maintenance painting agreements with Sara Lee, Tyson Foods, and Herbalife involve the application of industrial, high performance coatings. Because of the complexity of the services provided, QC now bills its customers at a relatively high rate, especially compared to the residential market. Higher rates are well warranted and pricing aspects are discussed in the following section. The same key factors that drive the price of commercial and industrial painting up are also factors that pose barriers for smaller, less established contractors trying to enter the market.

Cost Factors and Entry Barriers

Regulations

The purpose of this plan is not to chide the residential construction industry. There are plenty of builders and subcontractors operating very successful businesses working exclusively in the residential market. However, it is important to point out the differences in various sectors of construction—if for no other reason than to underscore QC’s competitive advantage potential. Most residential building is performed by self-employed (self-performing) builders and subcontractors. Other than superficial inspections conducted by local municipalities, there is no regulation or oversight on residential projects, particularly when it comes to painting. There is rarely a written contract between GC and subcontractor. Because there is no contract, there are no change orders, so extra work is performed at the subcontractor’s expense. Residential projects are seldom audited by OSHA7. There are no formal procedures for scheduling, invoicing, quality inspections, submittals, or closeout.

Conversely, in order to compete in the industrial sector, painting companies must comply with strict rules and regulations administered by OSHA, SSPC8, EPA9, Suppliers, Project Owners, CMs, Surety Companies, and The Department of Labor. Contrary to the claims of the Department of Labor, these requirements drive operating costs up significantly. The majority of small companies either cannot afford, refuse to comply with, or simply do not understand these mandatory regulations.

QC has successfully completed the pre-qualification process with a number of CMs and continues to pre-qualify for major projects in the region. Since 2006 the company has been developing standard operating procedures, safety policy and forms, and workmanship standards which meet or exceed industry requirements. The company has compiled an on-the-job safety record which meets all industry benchmarks. As expounded on later in this plan in Section 2.4, QC continues to put together a comprehensive quality and safety operating system, or Total Quality Management system (TQM)10, which is positioning the company as a unique organization—one much sought after by serious companies competing in today’s quality and safety obsessed work environment. It is a goal of the company to obtain multiple certifications with the major accreditation firms OSHA, SSPC, and NACE11.

Process and Product Knowledge

High performance and high priced materials present problems for smaller, less experienced painting contractors. Even the experienced contractor can be burned by the potential problems these products pose. It is vital that installers have a thorough understanding of the volatile product characteristics and the complex processes required to successfully apply high performance coatings. Cost, process, and product knowledge are the key components that keep a lot of painting contractors from competing in the industrial construction arena. In reality, it is what keeps QC from competing in certain subsectors of the industry, e.g., water towers, cellular towers, and nuclear power plants.

It is common to spend more than $350 for a single two-gallon kit of high solids polyurethane, and high temperature coatings can run in excess of $400 per gallon. An ill prepared surface can easily result in thousands of dollars in wasted time and materials—not to mention the irreparable damage to one’s reputation. It is difficult for CMs and project owners to accurately qualify a coatings contractor for a specific project requirement or application. QC is currently in the process of compiling a set of documents and certifications that will provide project managers the information they need to thoroughly assess the qualifications and capabilities of the company.

Administrative and Overhead

During QC’s transition from residential and light commercial to industrial painting, the administrative and overhead costs became clear very quickly. The company’s first introduction to the industrial construction industry was a contract with Zachry to paint Wyeth Vaccines’ new CUB building. There were easily forty hours logged just preparing the paperwork required to execute the contract. The amount of office support required to support the field operations is substantial and requires a certain level of technical skill to execute properly. Training records, NDAs, Drug Screens, Schedule of Values, Insurance Certificates, Material Submittals, Change Orders, Safety Plans, and Federal, State, and Local Government documents all have to be filed with the customer before any crews are mobilized. This can be very taxing on small businesses and poses another entry barrier for a lot of painting companies.

Other expenses that are commonplace to industrial painting contractors are insurance requirements with $10M coverages, bid bonds, payment and performance bonds, legal fees, accounting services, equipment leases, and travel. Most projects require the leasing of heavy equipment such as booms, scissor lifts, swing staging, and scaffolding. Using this equipment adds additional paperwork, insurance requirements, and training costs, e.g., fall protection plans, safety plans, operator training, and a variety of Personal Protection Equipment (PPE).

QC spent $100K on travel in 2014. Most of the company’s work is outside the Triangle Area. These are costs that are paid upfront which eats cash. With sixty to ninety day payment terms being the standard for most companies, managing cash flow is key to being successful. Again, this is one of the more notable barriers to entering into, and successfully competing in, the industrial painting market. Hotel, per diems, fuel costs, and idle time for lack of work are all genuine expenses that have to be funded well in advance of progress payment receipts.

Summary

The preceding high level overview of the company’s history highlights a few of the obstacles QC has already surmounted in its first decade of doing business. The company has managed to navigate the industrial construction’s entry barriers, and while doing so has created a respectable customer clientele. It has had its share of up and down years but has managed to stay financially healthy and has kept its good reputation intact. Coming off a record year in revenue and profit, the company is poised to take advantage of its current situation and generate significant growth over the next five years.

With the right staff, financial and legal partners, consultants, and accounting firm, QC should make quick progress toward becoming one of the premier painting companies in the Triangle Area. As laid out in the ensuing plan, the Founder expects the company to make significant advances in the next two years. Within the next five years QC painting crews will be a familiar sight on industrial construction projects all across North Carolina and its bordering states.